Monitor and Control

Combining

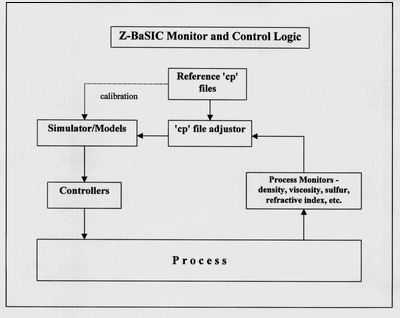

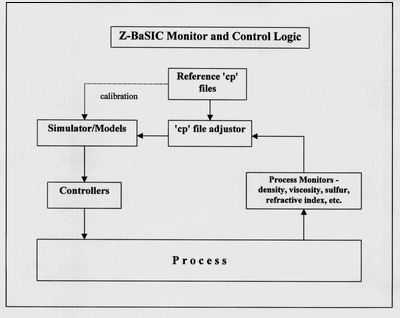

Monitor and Control provides a higher level of decision-making than traditional methods. The logic shows a reference 'cp' file that is updated through information provided by on-line monitors. The updated 'cp' file is input to 'smart' models (or simulators) that accurately anticipate the relationship between specifications and setpoints and make informed decisions about how to operate to achieve precise results.

By contrast, traditional systems use models and simulators that take the monitored values directly. Because the relationship between monitored values and desired specifications is generally emperical, the relationship is often inexact, leading to unexpected and undesirable results. Today's refiner simply lives with the inexactness and makes it up in the downstream processing or blending. This, however, requires greater inventory and additional care with meauring specifications that would not be required if the process results were precisely as expected.

Development Status

– There are no Z-BaSICTM control systems currently installed. The nearest-term system is for blend control, which is expected to be available by September, 2001.Email Applications Bulletin - 01C2